“ASU is in a unique position to scale up our testing efforts to support round-the-clock testing and analyze hundreds of samples daily,” said Joshua LaBaer, director of ASU’s Biodesign Institute, who also serves as the Piper Chair in Personalized Medicine and leader of the Biodesign Virginia G. Piper Center for Personalized Diagnostics. “We have an urgent window right now to make an impact through testing and save lives in our community.”

TRIF, the Technology & Research Initiative Fund has been an essential catalyst in developing the Biodesign Institute at Arizona State University. TRIF funding has supported the creation of the institute’s key research capabilities. These are now being leveraged to respond to the COVID-19 health emergency.

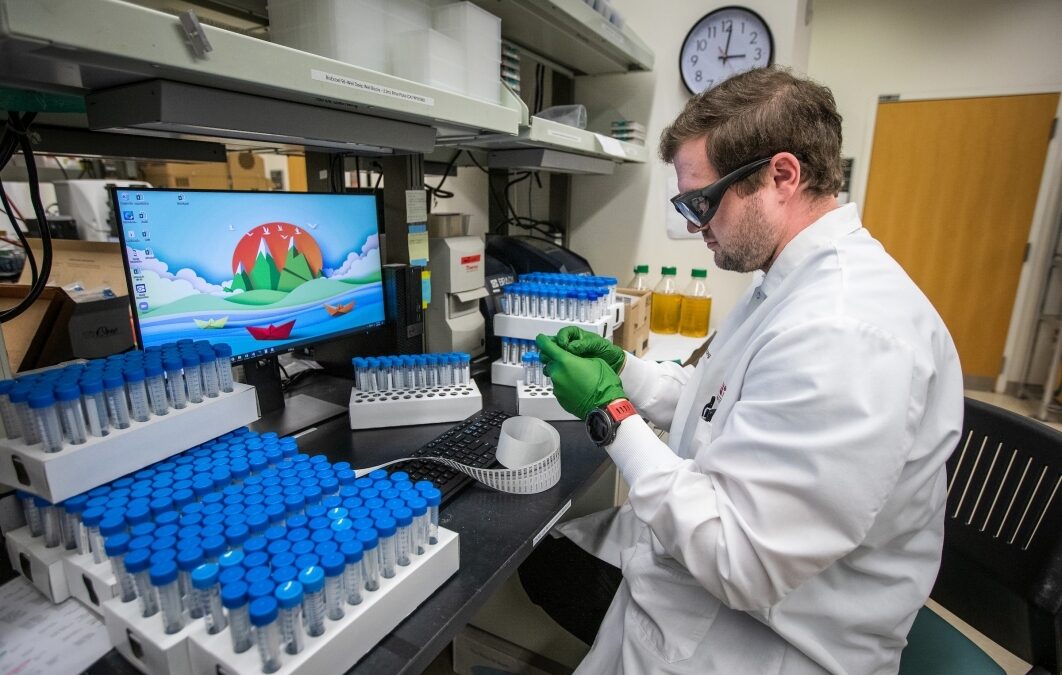

As capacity for COVID-19 testing became problematic and plagued by shortages in the supply chain for testing kits and reagents, LaBaer’s team of 100-plus core scientists, staff and students sprang into action.

In just two weeks, the Biodesign Institute shifted its research capabilities to support a clinically approved and certified COVID-19 testing center, a COVID-19 swab test kit production facility capable of assembling 2,000 kits per day, production of personal protective equipment such as face shields, and supporting drive-through COVID-19 testing currently underway at area hospitals.

This rapid shift was made possible by a Department of Defense $40 million investment in ASU back in 2009 as the lead contractor on a multi-year project aimed at helping to triage a population in the event of a nuclear emergency. The test developed by ASU could tell how much radiation a person was exposed to after a single explosive event.

“This particular tool was specifically for measuring the absorbed dose of gamma radiation exposure to civilians if a nuclear bomb were detonated in a city or populated area,” LaBaer said. “Now, we just swapped out the genes for radiation detection for the coronavirus ones to do the test. We have all the automation and robots in place, and everything’s ready to go now.”

The Biodesign Institute’s high throughput platform will run 400 samples a day at first, gathered from visitors experiencing COVID-19 symptoms who have been seen at various Valley-wide health care providers or their drive-in sites. The ASU team’s robotic system has the ability to run 1,000 samples a day at full capacity, greatly increasing Arizona’s COVID-19 local testing capabilities.

Community first

All of ASU’s research efforts are being coordinated with daily updates from meetings with Arizona health care providers in association with ASU’s clinical partnerships team, led by Sue Pepin, managing director, Health and Clinical Partnerships, and Tamara Deuser, associate vice president and chief operating officer, Knowledge Enterprise operations. Todd Hardy, ASU managing director of Innovation Zones; Mark Naufel, director of strategic partnerships; and Tyler Smith, associate director of the Luminosity Lab, are leading ASU’s 3D printing and manufacturing network to coordinate the hospital needs with the network’s ability to respond in real time.

ASU will also be reaching out to several municipalities, first-responder networks and the Arizona business community to help with COVID-19 preparedness in the days ahead.

“I am very proud of our faculty, staff, and students who are demonstrating the ability, capacity and commitment to take on this immense challenge — searching for innovative solutions to address the COVID-19 crisis,” said Sethuraman “Panch” Panchanathan, executive vice president of ASU’s Knowledge Enterprise and ASU’s chief research and innovation officer. “At ASU’s Knowledge Enterprise, we have been working tirelessly, and doing our best to replace community fears and anxiety with hope and a sense of unity to get through this crisis together.”

It’s a message LaBaer echoes every day to his team of hundreds of scientists, graduate students, technicians and freshly recruited volunteers as they deal with doing real-time, seat-of-the-pants science in a highly fluid COVID-19 pandemic environment.

“Let’s go save some lives.”

Summary by Joan Koerber-Walker based on an article written by Joe Caspermeyer at the ASU Biodesign Institute

Article Source: https://biodesign.asu.edu/news/asu-receives-2m-boost-coronavirus-rapid-research-response

Image Description: Nick Nabours, a research technician with DNASU Plasmid Repository, affixes bar code labels to test tubes that will be used in testing for COVID-19, at Biodesign A, on Monday, March 30, 2020. (Photo by Charlie Leight/ASU Now)